Ho tšoaea ka nickel nickel ea aluminium

Get Latest Price| Mofuta oa Lekhetho: | T/T |

| Incoterm: | FOB |

| Min. Laela: | 1 Bag/Bags |

| Lipalangoang: | Ocean,Land,Air |

| Mofuta oa Lekhetho: | T/T |

| Incoterm: | FOB |

| Min. Laela: | 1 Bag/Bags |

| Lipalangoang: | Ocean,Land,Air |

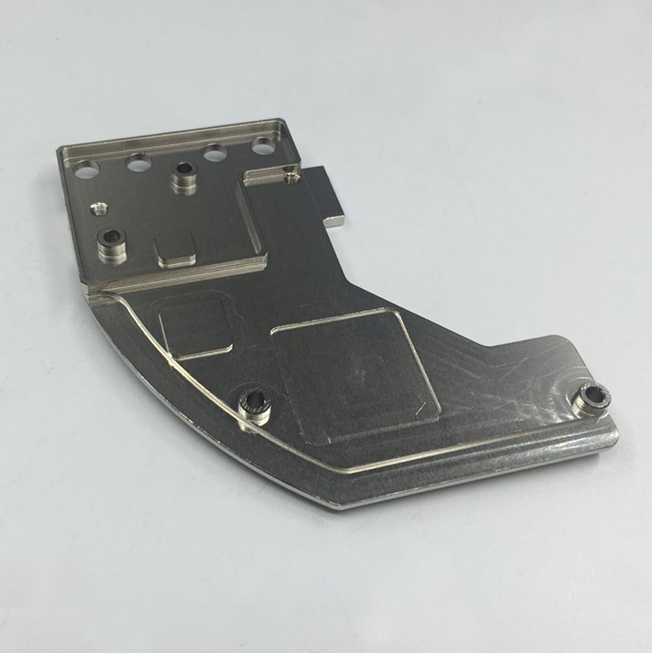

Setšoantšo sa No.: AL-096

Bakeng sa ho fokotsa boima ba 'mele, indasteri ea khale e sebelisa likarolo tsa aluminum ka mor'a ho ikhula, e joalo e ntse e eketseha, enjene ea motlakase . Ho na le likarolo tse ling tsa titanium tse sa lefelloeng le li-alloy tse sa lefelloeng li amohela khatello ea maikutlo le khatello ea maikutlo ea motlakase ea electroless le mehato e meng. Ts'ebeliso ea nickel e se nang motlakase ka har'a indasteri ea chelete e tšoana haholo. E sirelelitsoe ke elektrole ntle le motlakase, Nickel le ho bapala ka likarolo tse rarahaneng tse kang lefatše, le libaka tse haufi. Ho tšoaea nickel nickel e se nang motlakase ea radiator ea aluminium e na le ts'ebetso e ntle e ntle ea Brazing.

Setifikeiti se phethahetseng sa Ino9001: Setifikeiti sa "2008 sa Sistimi ea boleng ho netefatsa boleng ba sehlahisoa. Basebetsi ba boleng ba etsa litekanyo tse lekanang le likarolo tse ling tsa likarolo tsa cnc. Liletsa tsa ho lekanya: Digital Caliper ea Digital, li-calipeter tsa micrometer, bophahamo ba morara Ho nepahala ho sa lekanyetsoang tsa 0.001mm. Bakeng sa ho ntlafatsa lebelo la tlhahlobo, enjineri e thehile ka mokhoa o botsitso o entsoeng ka bokhabane. Re fana ka litlaleho tsa likarolo tsa mechini e hlophisitsoeng.

Re na le sehlopha sa theknoloji ea cnc lering. Mekhoa e Metle: Tlhahlobo ea Lihlahisoa, Tlhahlobo, Morero oa Cnc oa Lihlahisoa, Ho Tsamaisoa, Ho Sebetsa, Tlhahlobo ea boleng, Kelello ea boleng le lipalangoang. Basebetsi ba rona ba botekgeniki ts'ebetsong ea polasetiki ba nang le boiphihlelo bo bongata ba mofuta o mongata, o faneng ka polasetiki ea polasetiki. Hoo e batlang e le basebetsi bohle ka polasetiki ea polasetiki e tla etsoa ho thusa sebapali sa ho thibela sehlahisoa.

|

Business content |

CNC miliing, CNC turning |

|

Machining Processes |

CNC Milling, CNC Turning, CAM Programming, Sheet Metal Fabrication, Grinding, Cutting, Thread Turning, Milling Threasing, Tapping, Drilling, Knurling |

|

Machining Metal |

Titanium, Aluminum, Copper, Brass, Bronze, Stainless Steel, Steel, Delrin, Nylon, Neoflon, PTFE, Teflon, Ultem, Torlon, PEEK, Acrylic, PMMA,PC, Polycarbonate, PAI, PPS, PA, PET, PEI, PE, PVC, PP, ABS, PEP, PS, PSF, PI, PMMI, PABM |

|

Parts Size |

Milling Parts ( MAX) : Length 1030mm,Width 800mm, Height 750mm. Turning Parts ( MAX) : Diamter 680mm,Length 750mm. |

|

Tolerance |

0.01mm |

|

Equipment Capabilities |

CNC Machining Center, 3 Axis, 4 Axis, CNC Lathe, Lathe, CNC Turning Centers, Horizontal 8/12-position hydraulic turret, Milling Machine, Grinding Machine, Drill Press, Tapping Center, Rotary Indexer, Punch |

|

Secondary Services of Machining Parts |

Assemble, Plating Zinc Color (Machining Steel Parts), Anodize, Anodize Color, Hard Anodize, Hard Anodize Teflon (Machining Aluminum), Electroless Nicke (Machining Aluminum Parts, Machining Stainless Steel Parts, Machining Brass Parts ), Passivation ( Machining Stainless Steel parts ), Sand Blasting ( Machining Aluminum parts ), Brushed ( Machining Aluminum parts , Machining Stainless Steel parts ), Bluing and Blackening ( Machining Steel parts ), Trivalent Chromium Process ( Machining Aluminum parts ), Welding, brazing, soldering, Centerless Grinding and Burnishing |

|

Sample |

Samples are for free, sample time is 5 days. |

|

Delivery |

Delivery time is 3-4 week, depending on the degree of difficulty of machining parts |

|

file format |

Para-Solid 3D, PDF, IGES, STEP, SOLIDWORKS |

Re lebelletse ho ikopanya le uena hape. E-ba le letsatsi le letle 'me kea leboha ka kopo ea hau!

Polelo ea boinotšing: Lekunutu la hau le bohlokoa haholo ho rona. Khamphani ea rona e tšepisa hore ha e etse hore u se ke ua senola tlhahisoleseling ea hau ho ea pele.

Tlatsa tlhaiso-leseling e eketsehileng e le hore e ka ikopanya le uena kapele

Polelo ea boinotšing: Lekunutu la hau le bohlokoa haholo ho rona. Khamphani ea rona e tšepisa hore ha e etse hore u se ke ua senola tlhahisoleseling ea hau ho ea pele.