CNC MANEPING ALUMINUM TROTS

Get Latest Price| Mofuta oa Lekhetho: | T/T |

| Incoterm: | FOB |

| Min. Laela: | 1 Bag/Bags |

| Lipalangoang: | Ocean,Land,Air |

| Mofuta oa Lekhetho: | T/T |

| Incoterm: | FOB |

| Min. Laela: | 1 Bag/Bags |

| Lipalangoang: | Ocean,Land,Air |

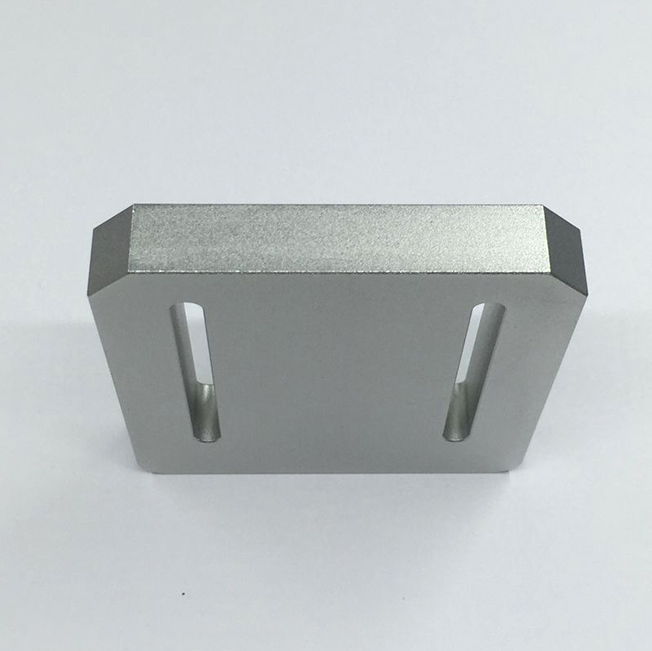

Setšoantšo sa No.: AL-191

Hobane nako e thusang ea CNC ho tsamaisa likarolo le lisebelisoa tsa aluminium e khuts'oane haholo, e lata le ho laolla likhoto tse tsamaeang haholo. Bakeng sa ho nolofatsa maemo le ho kenya, ho ccc ho lipeo tsa sheet le lisebelisoa, sefofane se seng le se seng sa ho hokahanya setsi sa mochini. CNC ho nang le likarolo tsa aluminium sheet le lisebelisoa, papali e lokela ho ba le likarolo tse fokolang le ho satalla haholo kamoo ho ka khonehang. Setšoantšo se lokela ho buloa ka hohle kamoo ho ka khonehang. Ho fokotsa boemo ba sebaka sa ho otla ha motho, ho molemo. Phihlelo e ke ke ea kena-kenana le tsela ea sesebelisoa sa mohato o sebetsang, ho etsa bonnete ba hore litaba tsa mochini tsa mochini oa mochine o phethoa ka botlalo sebakeng sa stroke sa stroke. Ntle le moo, ho CNC ho nang le likarolo tsa aluminium sheet le lisebelisoa, re lokela ho leka ho qeta sepakapaka tsohle tse nang le metjeko e le 'ngoe. Ha ho hlokahala ho fetola ntlha ea botsitso, tlhokomelo e khethehileng e lokela ho le lefu la ho se phethehe ho hotsoisisa ho tiisa ho tiisa ka ho nkela sebaka sa ho bolaea. Haeba ho hlokahala, ho lokela ho boleloa tokomane e kholo.

|

Business content |

CNC miliing, CNC turning |

|

Machining Processes |

CNC Milling, CNC Turning, CAM Programming, Sheet Metal Fabrication, Grinding, Cutting, Thread Turning, Milling Threasing, Tapping, Drilling, Knurling |

|

Machining Metal |

Titanium, Aluminum, Copper, Brass, Bronze, Stainless Steel, Steel, Delrin, Nylon, Neoflon, PTFE, Teflon, Ultem, Torlon, PEEK, Acrylic, PMMA,PC, Polycarbonate, PAI, PPS, PA, PET, PEI, PE, PVC, PP, ABS, PEP, PS, PSF, PI, PMMI, PABM |

|

Parts Size |

Milling Parts ( MAX) : Length 1030mm, Width 800mm, Height 750mm. Turning Parts ( MAX) : Diamter 680mm, Length 750mm. |

|

Tolerance |

0.01mm |

|

Equipment Capabilities |

CNC Machining Center, 3 Axis, 4 Axis, CNC Lathe, Lathe, CNC Turning Centers, Horizontal 8/12-position hydraulic turret, Milling Machine, Grinding Machine, Drill Press, Tapping Center, Rotary Indexer, Punch |

|

Secondary Services of Machining Parts |

Assemble, Plating Zinc Color (Machining Steel Parts), Anodize, Anodize Color, Hard Anodize, Hard Anodize Teflon (Machining Aluminum), Electroless Nicke (Machining Aluminum Parts, Machining Stainless Steel Parts, Machining Brass Parts ), Passivation ( Machining Stainless Steel parts ), Sand Blasting ( Machining Aluminum parts ), Brushed ( Machining Aluminum parts , Machining Stainless Steel parts ), Bluing and Blackening ( Machining Steel parts ), Trivalent Chromium Process ( Machining Aluminum parts ), Welding, brazing, soldering, Centerless Grinding and Burnishing |

|

Sample |

Samples are for free, sample time is 5 days. |

|

Delivery |

Delivery time is 3-4 week, depending on the degree of difficulty of machining parts |

|

file format |

Para-Solid 3D, PDF, IGES, STEP, SOLIDWORKS |

Melemo ea meputso ea CNC ke:

① Palo e kholo ea sesebelisoa e ka fokotsoa 'me likarolo tse nang le mechini e nang le libopeho tse rarahaneng ha li hloke lisebelisoa tse thata. Haeba u batla ho fetola sebopeho le boholo ba likarolo, li hloka feela ho fetola likarolo tsa mechini ea mechine ea nts'etsopele ea lihlahisoa tsa sehlahisoa le phetoho.

Bokaholimo ba lipere bo tsitsitse, ho nepahala ho ho nepahala hoa mekhoa ho phahama, 'me e loketse litlhoko tsa sefofane.

③ Ts'ebetso ea tlhahiso e phahame tlasa boemo ba mefuta ea mefuta-futa ea bongata, e ka fokotsang nako ea ho itokisetsa, le ho fokotsa nako ea ho khaola ka lebaka la tšebeliso ea palo e khaotsoeng.

Mekhoa e meng e nang le mekhoa e metle e sebetsa ho sebetsa mekhoeng e rarahaneng ka mokhoa, 'me e ka sebetsa likarolo tse ling tse sa tšoanelang.

Re lebelletse ho ikopanya le uena hape. E-ba le letsatsi le letle 'me kea leboha ka kopo ea hau!

Polelo ea boinotšing: Lekunutu la hau le bohlokoa haholo ho rona. Khamphani ea rona e tšepisa hore ha e etse hore u se ke ua senola tlhahisoleseling ea hau ho ea pele.

Tlatsa tlhaiso-leseling e eketsehileng e le hore e ka ikopanya le uena kapele

Polelo ea boinotšing: Lekunutu la hau le bohlokoa haholo ho rona. Khamphani ea rona e tšepisa hore ha e etse hore u se ke ua senola tlhahisoleseling ea hau ho ea pele.