Polelo ea boinotšing: Lekunutu la hau le bohlokoa haholo ho rona. Khamphani ea rona e tšepisa hore ha e etse hore u se ke ua senola tlhahisoleseling ea hau ho ea pele.

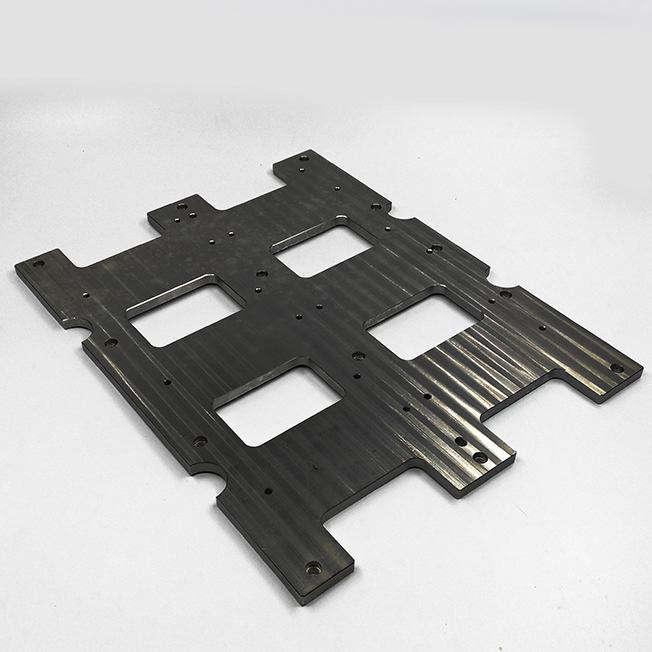

Joalokaha kaofela re tseba, lisebelisoa tse fapaneng tsa setsi sa mochini tse hlano-axis li ka fihlela lits'ebetso tse ruileng le tse feto-fetohang. Morero oa setheo sa pele sa mochini oa matsoho o iketsahallang oa makotla, re ka fihlela mochini o nang le boiphihlelo le o tšepahalang oa axis ka lebelo le hohelang le ka mahlale a tsitsitseng. Phetoho ea likarolo tse fapaneng tse arolelanoang, hammoho le moralo oa botebo ka tatellano ea lihlahisoa. Matsatsing ana, ho ne ho ka tseba le ho tiisetsa le ho tiiselitse ho ntlafalitse theknoloji ea litšebeletso tse hlano tse amanang le lithupelo tse tsamaeang ka tsela e potileng le tsoelo-pele ea nako. Ho latela lenaneo la eona la tlhahiso le lisebelisoa, e na le litšobotsi tse ikhethang tse ikhethang le tse fapaneng. Joale na ua tseba hore litšobotsi tse peli tse kholo tsa theknoloji ea machining a machining? Tse latelang ke kenyelletso e khuts'oane e tsoang ho mohlophisi oa moetsi oa axis ea axis ea axis.

November 15, 2024

November 15, 2024

November 15, 2024

November 15, 2024

E-mail ho mofani oa sena

November 15, 2024

November 15, 2024

November 15, 2024

November 15, 2024

Polelo ea boinotšing: Lekunutu la hau le bohlokoa haholo ho rona. Khamphani ea rona e tšepisa hore ha e etse hore u se ke ua senola tlhahisoleseling ea hau ho ea pele.

Tlatsa tlhaiso-leseling e eketsehileng e le hore e ka ikopanya le uena kapele

Polelo ea boinotšing: Lekunutu la hau le bohlokoa haholo ho rona. Khamphani ea rona e tšepisa hore ha e etse hore u se ke ua senola tlhahisoleseling ea hau ho ea pele.