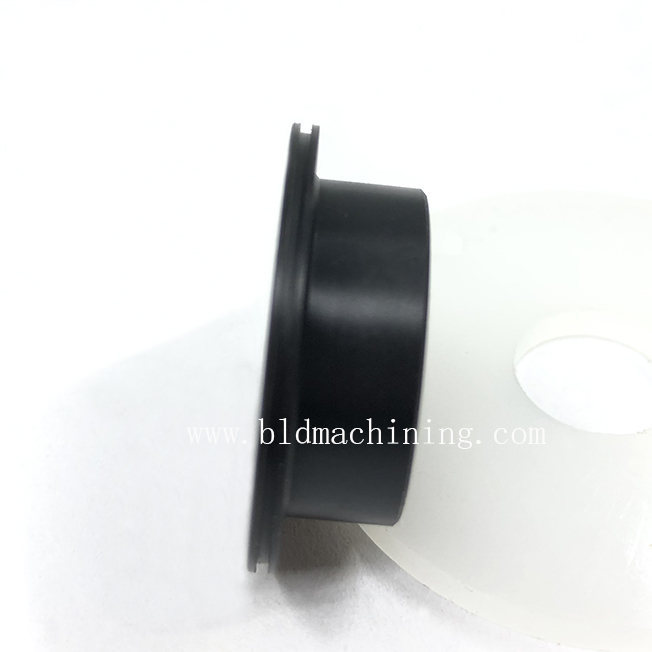

Karolo e holimo ea Lathe e fetotsoe likarolo tsa polasetiki ka grooves

Get Latest Price| Mofuta oa Lekhetho: | T/T |

| Incoterm: | FOB |

| Min. Laela: | 1 Bag/Bags |

| Lipalangoang: | Ocean,Land,Air |

| Mofuta oa Lekhetho: | T/T |

| Incoterm: | FOB |

| Min. Laela: | 1 Bag/Bags |

| Lipalangoang: | Ocean,Land,Air |

Setšoantšo sa No.: TU-065

Karolo e holimo ea Lathe e fetotsoe likarolo tsa polasetiki ka grooves

Ho ts'oaroa ha metjeko ea lama t urning ho arotsoe ka har'a groove ea kahare le groove ea kantle. Leroove e ka polasetiki ena e fetoha karolo ea groove ea kantle.

1. Bakeng sa Grooves e nang le phetoho e tlase e nang le ho fetoha e nepahetseng le e patisaneng, sekhechana se ka seroang ka ho fepa ka kotloloho ka nako e le 'ngoe. Lathe t Urning groove s e nang le ho nepahala ho feta e tloaetse ho etsoa ka koloi ea bobeli. Ka mantsoe a mang, ha leqhubu la ho fepa le sebelisoa ka mahlakore ka bobeli la lebota le lekantsoeng la sethala, le thipa ea bobeli ea ho phefumoloha.

Li-croo tse fetohe li ka khaoloa ka ho hlaka haholo. Chelete e itseng ea ho qeta nako e setseng e siuoa ka mahlakore ka bobeli a lebota le lerako. Ebe, ho ea ka botebo bo koroboet le bophara ba koroko, ba phethela ho kenya mokhoa oa ho taka.

3. Ho fetola li-grooves tse nyane tsa ARC, hangata ka ho etsa sehiloeng ho fetoha. Grooves e kholo ea arc e ka fetoloa ka likhokahano 'me e hlahlojoe ebile e entsoe ke template.

4. Ho fetola li-grooves tse nyane tse tloaelehileng hangata ho etsoa ka ho theha likhetla. Hangata li-groove tse kholo tse kholo li etsoa ka ho fetola li-grooves tse otlolohileng pele, pele ho sebelisa mokhoa o sa tobellang oa Trapezolidal.

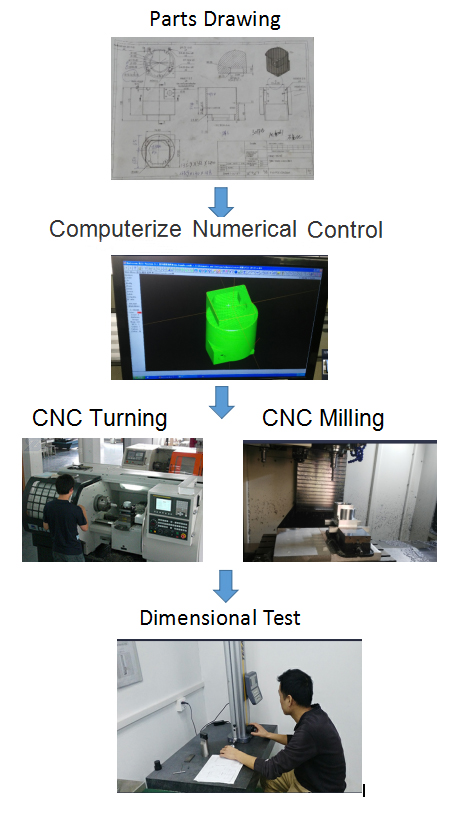

Karolo e matla ea ho khutlisa e le hore e be matla ka boitokisetso e ho etsa bonnete ba hore motheo oa sehlahisoa sa sehlahisoa, lienjiniere tsa rona li tsepamisitse maikutlo ho ntlafatsa ho feto-fetoha le nako le ho tsamaisa meching theknoloji. Kutloisiso e felletseng le Monghali oa ho fetola CNC le CNC ea CNCing ea CNCing e hlahisang ts'ebetso ea mantlha le mahlale a sehlooho. Boitšoaro bo sebelisang cad / HD / Agn Cam Ts'ebetsong ea bohlokoa ea ts'ebetso e lokela ho hlahlojoa tlhahlobo ea phetoho ea mamati ea ho fetola.

Ha a haha sehlopha sa sehlopha, LTD ke moetsi oa litsebi oa CNC le CNC Opening litšebeletso le lits'ebeletso tsa boyring bakeng sa likarolo tsa om and odm. Lihlahisoa tsa rona tsa cnc tsa cnc le cnc tsa cnc li:

|

Aluminum |

6061, 6061-T6, 6063, 7075, 5052, 2024, 2017, 6082 |

|

Copper |

Copper, Brass, Bronze |

|

Stainless Steel |

SUS303, SUS304,( 57333944, 57327748, 57266856, 57158587, 56720232, 56707289, 56674195, 56664771, 54400552, 54383354, 54153424, 54147929, 54138846, 54131278, 54067234, 54065431, 54025957,1.4301), SUS316 |

|

Steel |

Q235, 45 #, A3, 718H, S136, SKD11 |

|

Titanium |

|

|

Plastic |

Delrin, Nylon, Neoflon, PTFE, Teflon, Ultem, Torlon, Peek, PMMA, PC, PAI, PPS, PA, PVDF, POM, PA, PET, PEI |

Ntle le moo, re fana ka lihlahisoa bakeng sa lits'ebeletso tsa hau tsa tšebetso ea bobeli ea ts'ebetso : Anodize (e hlakileng, e putsoa, e putsoa, e putsoa

Ho kenella ka ho ikemela ka bokhachane ho ka hlahisa lifaele tsa hau tsa litšoantšo tse tiileng tsa 3D, PDF le IPS, mehato ea li-appw. Ka kopo romella ka mosebetsi oa hau oa 3D le PDF bakeng sa qotsulo.

Litšobotsi tsa rona:

Polelo ea boinotšing: Lekunutu la hau le bohlokoa haholo ho rona. Khamphani ea rona e tšepisa hore ha e etse hore u se ke ua senola tlhahisoleseling ea hau ho ea pele.

Tlatsa tlhaiso-leseling e eketsehileng e le hore e ka ikopanya le uena kapele

Polelo ea boinotšing: Lekunutu la hau le bohlokoa haholo ho rona. Khamphani ea rona e tšepisa hore ha e etse hore u se ke ua senola tlhahisoleseling ea hau ho ea pele.